Additive manufacturing involving titanium and aluminium alloys

The additive manufacturing of metal parts represents a real industrial revolution that challenges traditional manufacturing processes. This innovative process should make it possible to reduce the time and costs of manufacturing metal parts in order to maintain the competitiveness of manufacturers.

Several metal additive manufacturing technologies have been developed, but two identified processes have characteristics that can meet the needs of manufacturers in the aeronautics, automotive and energy sectors.

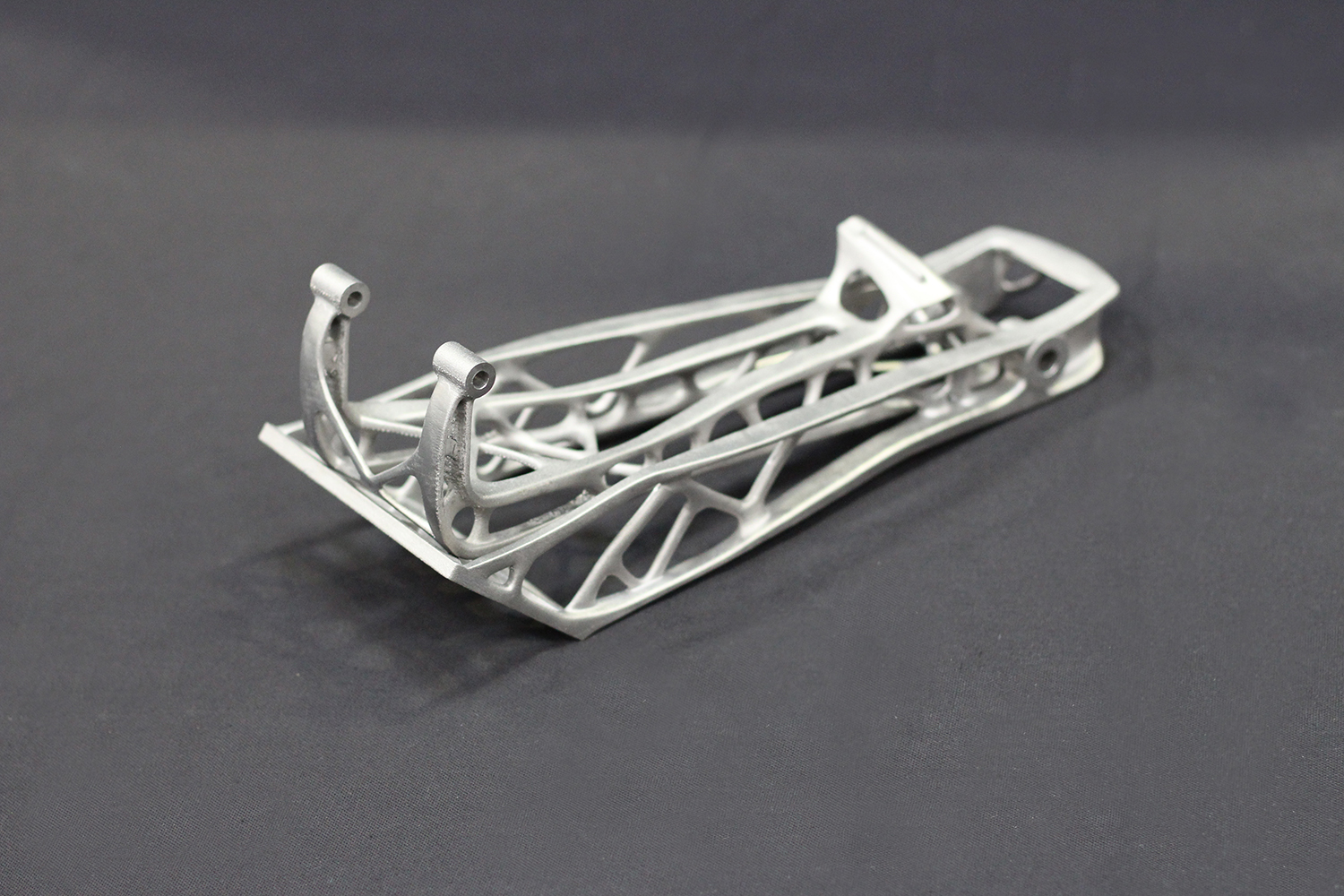

The project concerns the development and comparison of two metal additive manufacturing processes: laser projection (or Direct Metal Deposition – DMD) and laser powder bed fusion (or Selective Laser Melting – SLM) for the production of parts for the aerospace, automotive and energy industries.

Les résultats

Within the frame of the project, DAHER commissioned IRT Jules Verne to carry out characterization tests on the prototype of the titanium step using the additive manufacturing process studied.

Industrial impacts

- Optimisation of performance of parts

- Reduced manufacturing times

- Reduce manufacturing costs

Valorisations

- DAHER’s titanium step case study is a convincing example of how all the expertise and equipment of IRT Jules Verne can be used to carry out a global industrial R&D project, from the first simulations to the final tests, including the design and manufacture of the part using a powder additive manufacturing process.

- Watch the video of the project! Click here.

Expertise

- Metal processes

Partners

- IRT Jules Verne

- ACB

- ARTS ET MÉTIERS ANGERS (LAMPA)

- CENTRALE NANTES (IRCCyN)

- DAHER

- EUROPE TECHNOLOGIES

- FIVES

- RENAULT

- UNIVERSITÉ DE NANTES (GeM ET IMN)