Final review of the European CARBO4POWER Project: Collaborative innovations for the energy of tomorrow

On October 22-23, 2024, the final review of the CARBO4POWER project was held at IRT Jules Verne, bringing together all 17 project partners. During this event, the demonstrators developed throughout the project were presented to the entire consortium, the Project Monitor, Dr George Kotsikos and the reviewer, marking a significant milestone in the project’s completion.

Overview of the CARBO4POWER Project

To recap, the CARBO4POWER project aimed at developing innovative technologies for the manufacturing of marine energy system components, such as wind and tidal turbines, using advanced composite materials. These innovations were designed to address several key challenges: reducing production costs, improving the mechanical performance of components, and decreasing their environmental impact.

The project focused on multiple areas, including the development of new composite materials, optimized manufacturing processes, and the integration of structural health monitoring solutions to enhance the durability and safety of marine systems.

Contributions of IRT Jules Verne

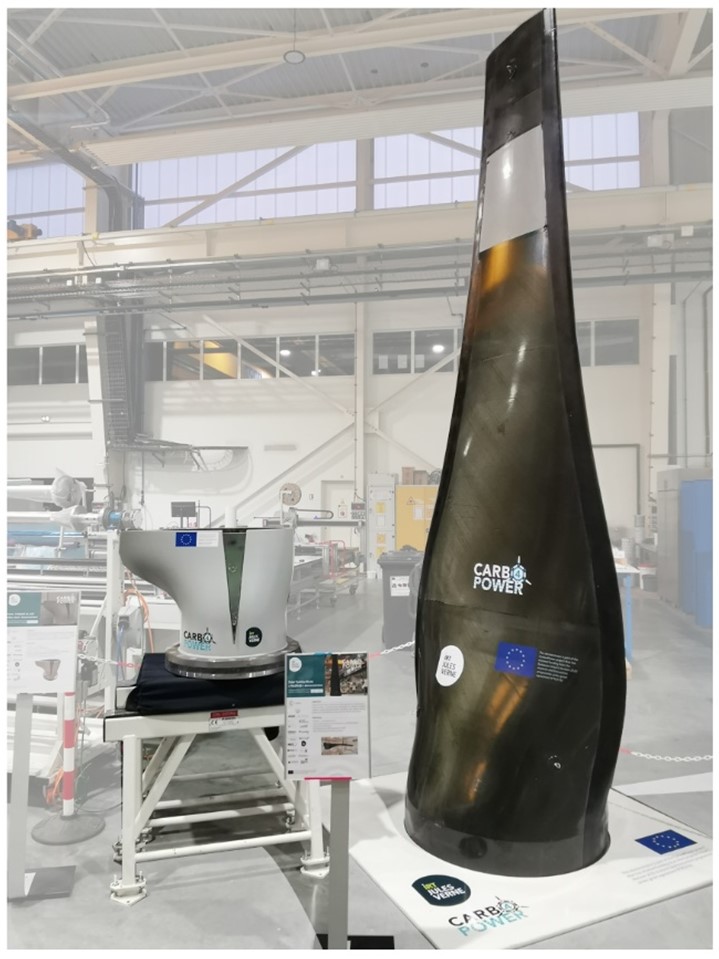

Within this project, IRT Jules Verne played a central role in developing several key demonstrators. One notable contribution was the re-design and manufacturing of a full-scale (truncated) tidal turbine demonstrator that incorporated a new formulation of 3R Vitrimer resin. This innovative resin enables the recycling, repair, and reshaping of components, paving the way for more sustainable solutions in the marine energy sector.

The demonstrator also included QRS sensors for structural health monitoring (SHM) and a textured anti-fouling coating for drag reduction. Thanks to tests carried out on the multi-actuator test bench at IRT Jules Verne in Angers, the mechanical performance of this new resin was validated. The results were comparable to those of commercial thermosetting resins, confirming the material’s viability for industrial applications.

In parallel, a second demonstrator was developed: a one-third scale tidal turbine blade root. This demonstrator was produced using an innovative One-Shot process, which ensures continuous reinforcement between the skins while significantly reducing production time.

Towards cost and environmental impact reduction

Techno-economic analyses and life cycle assessments of these demonstrators revealed promising results. Depending on the case, the use of 3R resin and automated lay-up or One-Shot processes could reduce production costs by 10-20% and environmental impact by 35-45%. These advancements represent an important step toward more competitive and eco-friendly solutions for the marine energy industry.

A challenging and successful project

“We are proud to have contributed to this particularly challenging project and to have tackled, alongside our partners, the obstacles it presented. The completion of CARBO4POWER is the result of effective collaboration, where everyone was able to bring their expertise in a positive and productive working environment. We would like to thank all the partners for their dedication, hard work, and excellent cooperation throughout the project,” concluded Céline Constantin, Project Manager at IRT Jules Verne.

Thanks to these joint efforts, CARBO4POWER offers a promising future for the integration of innovative technologies in renewable energy, addressing the economic and environmental challenges of tomorrow.