Follow our news

In French only

New step for the DESCARTES project: reception of the first prototype tooling of a fuselage frame section

CERO, one of our partners in the project, has designed and produced this first tool that will be implemented on the PINETTE press just commissioned in the IRT Jules Verne. The reception of this first tooling is a key step that will allow to continue the development on the different steps of the process. […]

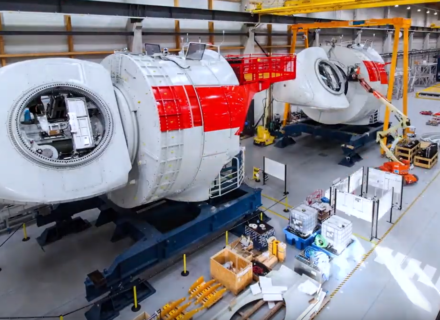

IRT Jules Verne launches ‘ZEBRA project’ to develop 100% recyclable composite wind turbine blades with industrial partners

Wind energy, both onshore and offshore, plays a critical role in the world’s transition to carbon-free energy sources. With a product lifespan of 30 years and a wind turbine recyclability rate of 85% to 90%, the wind power industry is now looking to close the remaining gap by designing and manufacturing the first 100% recyclable […]

CORONAVIRUS

Because health is our priority, and given the latest strict containment measures taken by French President, IRT Jules Verne adapts its organization. Our priority : to protect our staff and contribute to brake the virus spread while maintaining as much as we can a continuity of our activity. Therefore, all IRT […]

Discover the SIDEFFECT project

Discover the SIDEFFECT project : Continuous induction welding, a technical challenge for thermoplastic fuselage. The SIDEFFECT project aims to develop and evaluate dynamic induction welding for thermoplastic fuselage in a low cost and high speed context. The final demonstrator integrates the geometric complexities representative of a fuselage panel. Watch the video :

Discover the SHORE project

Discover the SHORE project: Assessing the health of assemblies on offshore wind turbines through video monitoring with interviews with IRT Jules Verne, General Electric and Gustave Eiffel University. The objective of this project is to identify an optimal monitoring method to assess the health status of the targeted assemblies and welded assemblies (e.g. loss […]

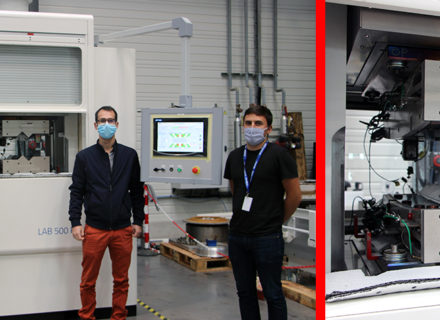

IRT Jules Verne, Airbus and Fives Machining launch MADRAS automated textile deposition line for WING project

The IRT Jules Verne & its partners Airbus, Loiretech & Fives Machining inaugurated, on Thursday 13 February, the automated manufacturing line for textile composite preforms MADRAS in the presence of Stéphanie Houel. The implementation of this 18-metre long line including three robotic islands marks a key stage in the WING project. Launched in […]

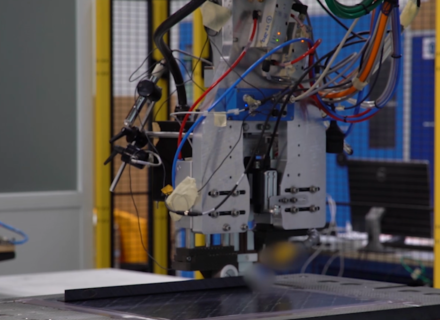

DISCOVER THE WING PROJECT IN VIDEO

Discover the WING project: High volume deposition & preforming line in video with interviews of Airbus, Fives & Loiretech. The objective of the project is to evaluate the capacity of textile technology to meet the high production rates of the aeronautics industry for large parts with complex geometry and dimensions. Research topics include: preform […]