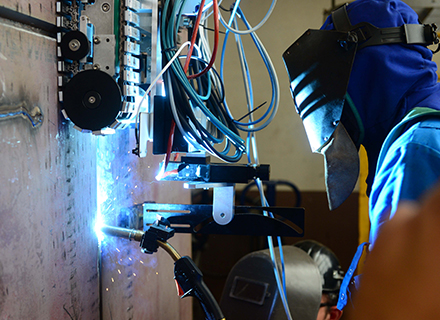

Autonomous robotised carriage muti-task for shipyard applications

In the naval sector, the assembly of prefabricated blocks is carried out by manual welding, in a complex environment requiring the installation of expensive scaffolding.

The purpose of the CHARMAN project is to develop a stand-alone welding trolley with the capability to move and automatically adjust its path on vertical surfaces, and to correctly repair welding seams as a function of the section of the weld joint.

Results

This project ended in January 2016 with conclusive results for industrialists, which made it possible to launch a second collaborative research project aimed at achieving the industrialisation of the product, bringing together the Jules Verne IRT, Servisoud and the Chantiers de l’Atlantique.

Industrial impacts

- No need for scaffolding for edge welding operations: €300,000 saved

- Improved weld reproducibility and quality

- Lower risk of accidents and better working conditions

Valorisations

Expertise

- Robotics & cobotics

Partners

- IRT Jules Verne

- BUREAU VERITAS

- NAVAL GROUP

- SERVISOUD

- Chantiers de l’Atlantique

- LS2N (UMR CNRS, ECN, EMN, UNIVERSITÉ NANTES)