Production

AFAL project completion

The feasibility study, AFAL, initiated in 2021 with DAHER, ended a few days ago. In the current context, automatic draping technologies are poorly adapted to small parts and require the intervention of specialised operators. While their skills are essential for complex parts, it is interesting to think about automation for simpler parts. In this […]

LAUNCH OF THE HYBRITECH PROJECT TO MEET THE REQUIREMENTS OF THE AERONAUTICAL SECTOR, PARTICULARLY WITH REGARD TO THE ENVIRONMENTAL IMPACT OF THEIR PROCESSES

The IRT Jules Verne and its partners, AIRBUS and LOIRETECH, have just launched the HYBRITECH project for a duration of 36 months and a budget of 2.8M€. Composite materials for aeronautical applications and their implementation are now widely mastered. However, the context of increasing aeronautical production rates requires a review of aspects of the […]

DISCOVER THE MOVIE ON ZEBRA PROJECT

The ZEBRA (Zero wastE Blade ReseArch) project today marks an important step in the industry’s transition to a circular economy with the completion of a 62m prototype blade made from Elium® resin, a thermoplastic resin known for its recyclable properties, and new high performance fibreglass materials. Discover now the dedicated film : To […]

Launch of the 3DCALOR project for the additive manufacturing of heat exchangers

The IRT Jules Verne and its partners, Fives (Manufacturing of heat exchangers), AddUp (Additive Metal Manufacturing and 3D Printing) and the CNRS/LTEN (Laboratory of Thermics and Energy of Nantes) have launched the 3DCALOR project for a duration of 12 months. In the current context of increasing the performance of heat exchangers, the consortium will […]

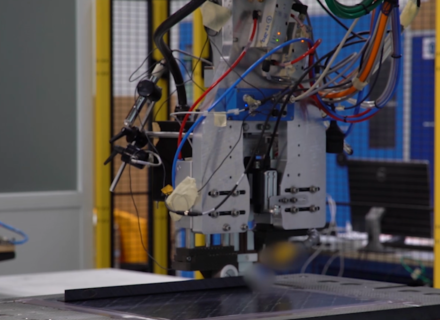

ASPEN project: cobotised welding assembly solution for a naval application on flat panels

The ASPEN project, started in 2016 with Europe Technologies, Naval Group, Chantiers de l’Atlantique, CETIM & LS2N has just completed an important milestone, the delivery of the last cobot! In shipbuilding, many welding operations are performed manually. The ASPEN project therefore aimed at robotising welding operations on a flat panel application to reduce the […]

Completion of ROCABLE project

The European ROCABLE project, initiated in 2020 with the IRT Jules Verne, INRIA, EES-Clemessy ADS and piloted by the CNRS with the LS2N, ended a few days ago. The project partners, all experts in the field of robotics, presented the results obtained during these 9 months of development. Towards collaborative use of Cable-Driven Parallel […]

Completion of the WING project

The WING project initiated in 2017 by IRT Jules Verne with AIRBUS, Fives Machining and Loiretech has just been completed. This emblematic project of the Institute aims to evaluate the capacity of textile technologies to meet the high production rates of the aeronautical industry for the manufacture of large parts with complex geometries. A […]

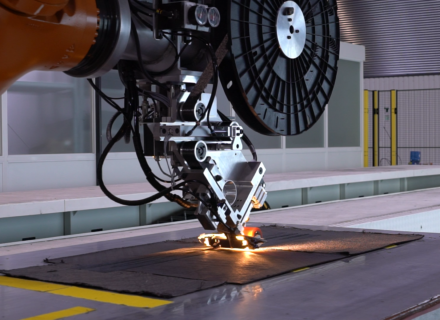

Discover the SIDEFFECT project

Discover the SIDEFFECT project : Continuous induction welding, a technical challenge for thermoplastic fuselage. The SIDEFFECT project aims to develop and evaluate dynamic induction welding for thermoplastic fuselage in a low cost and high speed context. The final demonstrator integrates the geometric complexities representative of a fuselage panel. Watch the video :